Top Push Pull Latch Hardware for 2025 The Ultimate Guide to Selection and Use

As industries continue to evolve in the face of technological advancements, the demand for reliable and efficient hardware solutions remains paramount. The push pull latch hardware sector is no exception, projected by the Global Fastener Association to experience a compound annual growth rate (CAGR) of 5.2% over the next five years. These devices play a critical role in a myriad of applications, offering enhanced security and ease of use across various industries, from automotive to aerospace.

Expert John McAllister, a leading figure in fastening technology, emphasizes the importance of selecting the right push pull latch hardware, stating, "The quality of latch mechanisms can make or break operational efficiency. In the competitive landscape of manufacturing, every detail counts." As we navigate through 2025, understanding the intricacies of these latches—such as material selection, load capacities, and environmental considerations—will be essential for engineers and designers alike. This guide aims to illuminate the best practices for selecting and utilizing push pull latch hardware, ensuring optimal performance and longevity in your projects.

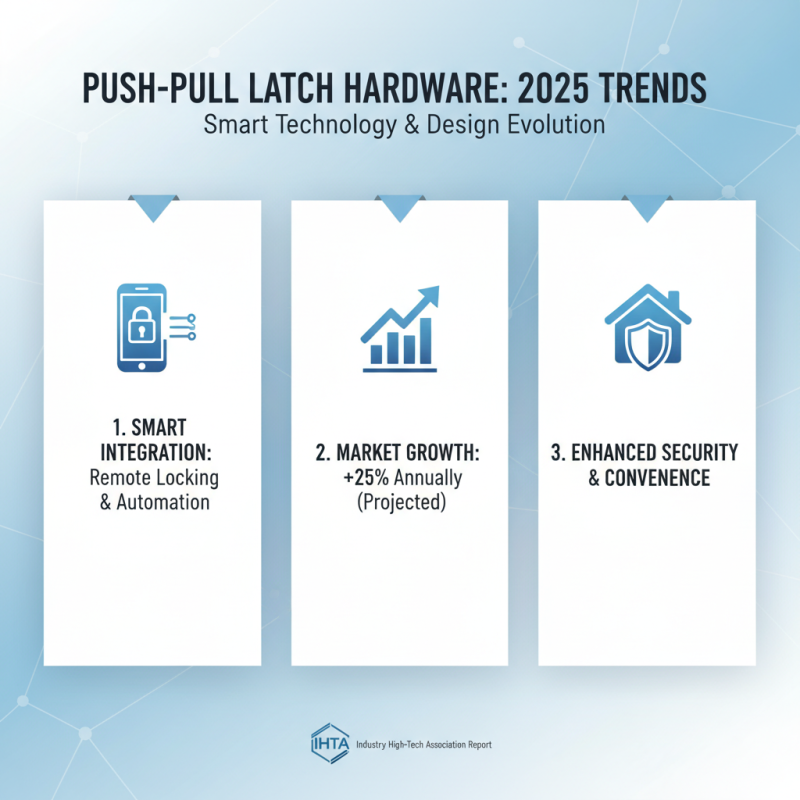

Top Trends in Push Pull Latch Hardware for 2025

As we look toward 2025, the landscape of push-pull latch hardware is set to evolve significantly, reflecting broader technological trends and design preferences in the hardware industry. One of the key trends is the increasing integration of smart technology into conventional latch systems. According to a recent report from the Industry High-Tech Association, the market for smart latching devices is projected to grow by 25% annually, driven by the rising demand for enhanced security features in residential and commercial applications. This shift not only enhances user convenience but also incorporates advanced functionalities such as remote locking and automation, which are becoming essential in modern architectural designs.

In addition to technological advancements, sustainability is becoming a central theme in the development of push-pull latch hardware. A study by the Center for Green Building Technologies indicates that more manufacturers are prioritizing eco-friendly materials and production methods, as consumer awareness around sustainable practices continues to rise. By 2025, it is anticipated that over 60% of latch hardware will be made from recycled or sustainably sourced materials. This trend not only reduces the environmental footprint but also appeals to a growing demographic of environmentally-conscious consumers who prioritize sustainability in their purchasing decisions. As such, the industry is adapting to meet these evolving expectations, positioning itself for a more innovative and environmentally-friendly future.

Key Materials Used in Push Pull Latch Manufacturing

The manufacturing of push pull latches involves a variety of materials that significantly influence their performance and longevity. Commonly used materials include stainless steel, zinc alloy, and plastic composites. Stainless steel is favored for its durability and corrosion resistance, making it ideal for harsh environments. According to industry reports, the global stainless steel market is projected to grow at a CAGR of 5.8% through 2025, driven largely by its widespread application in industrial hardware, including latches. This growth underscores the importance of selecting the right material when considering the operational lifespan of these components.

Zinc alloys, on the other hand, offer a cost-effective solution while maintaining a decent strength-to-weight ratio. These materials can be treated with various surface coatings to improve their resistance to wear and tear, enhancing their functionality in push pull latch applications. A report from the Global Zinc Alloy Market indicates that the demand for zinc alloys is projected to increase due to their versatility and application in automotive and construction sectors, which are also seeing parallel growth in hardware applications. Moreover, advancements in plastic composite technology are leading to the development of lightweight latches that retain strength without the corrosion issues associated with metal, making them suitable for both indoor and outdoor environments.

Performance Metrics: Evaluating Push Pull Latch Durability and Efficiency

When selecting the best push-pull latch hardware, evaluating performance metrics such as durability and efficiency is crucial. Durability typically refers to a latch's ability to withstand wear and tear over time, influenced by factors such as material composition and construction quality. High-quality materials like stainless steel or reinforced polymers can significantly enhance the lifespan of a latch, making it more resistant to corrosion, impacts, and repeated use. Furthermore, testing under various environmental conditions can provide insights into how a latch will perform in the field, ensuring it meets specific application demands.

Efficiency, on the other hand, involves how effectively a latch operates under normal load conditions. This includes the smoothness of the opening and closing mechanism, as well as its responsiveness to user input. Evaluating these aspects often requires assessing the latch's design, including features like ergonomic handles and spring mechanisms that aid in its function. A well-designed latch not only streamlines operation but also reduces strain on users, contributing to overall satisfaction and safety. By prioritizing both durability and efficiency in your selection process, you can ensure that your push-pull latches will perform reliably in various applications throughout 2025 and beyond.

Push Pull Latch Performance Metrics for 2025

Installation and Maintenance Best Practices for Push Pull Latch Systems

When it comes to the installation and maintenance of push-pull latch systems, attention to detail can significantly enhance the performance and longevity of these hardware components. According to a report by the National Hardware Institute, improperly installed latching mechanisms result in a 25% decrease in reliability and safety in industrial applications.

Properly aligning latches during installation is crucial, as misalignment can lead to undue wear and potential failure. It is recommended to ensure that the latch engages smoothly with the strike plate by using appropriate spacers or shims during the setup process.

Regular maintenance practices are equally essential for the optimal functioning of push-pull latch systems. The American Association of Mechanical Engineers (AAME) suggests implementing a bi-annual inspection routine to check for signs of wear, corrosion, or misalignment. Lubrication with non-corrosive oils can prevent sticking and ensure smooth operation, increasing the lifespan of the system.

It’s also vital to tighten any loose screws or fittings, as even minor looseness can compromise the effectiveness of the latch. Such maintenance routines not only enhance durability but can also reduce long-term replacement costs by addressing minor issues before they escalate.

Market Forecast: Growth of Push Pull Latch Hardware Industry by 2025

The push pull latch hardware industry is poised for significant growth as we approach 2025. According to recent market research reports, the global demand for push pull latch hardware is expected to increase at a compound annual growth rate (CAGR) of 7.5%, driven largely by advancements in technology and manufacturing processes. The rising applications of these latches in various sectors, including automotive, electronics, and industrial machinery, are attributed to their ease of use, reliability, and security features.

Furthermore, the market forecast indicates that the expansion of the construction and infrastructure sectors will create additional opportunities for push pull latch hardware. As new buildings and facilities require more sophisticated locking mechanisms, the demand for innovative latch solutions is anticipated to rise. The estimated market value for push pull latch hardware could surpass $1 billion by the end of 2025, marking a notable uptick in investment and innovation, which includes increased automation and sustainable materials. With these developments, industry professionals must stay informed about emerging trends and technologies to utilize push pull latch hardware effectively in their projects.

Related Posts

-

2025 Top 5 Aluminum Motor Housing Innovations You Need to Know

-

Maximize Your Ride: The Ultimate Guide to Non-OEM Car Parts for Every Budget

-

10 Essential Tips for Choosing the Right GM Column Shifter Spring

-

2025 Guide: How to Choose the Best PSC Steering Box for Your Duramax

-

Why Upgrading to PSC Steering Box Duramax Enhances Your Vehicle's Performance

-

Essential Guide to 2025 Top Tilt Steering Column Parts for Trucks