Top 10 Motor Bearing Housing Solutions for Optimal Performance and Longevity

In the dynamic world of mechanical engineering, the efficiency and durability of motor systems heavily rely on the performance of motor bearing housings. These components play a critical role in supporting the bearings and ensuring smooth operation under various conditions. According to a recent report by the International Journal of Mechanical Engineering, nearly 45% of motor failures are attributed to bearing-related issues, emphasizing the necessity for reliable motor bearing housing solutions.

Expert insights underscore the importance of selecting the right motor bearing housing. Dr. James Lancaster, a renowned engineer in the field, stated, "The choice of motor bearing housing is pivotal for optimal performance and longevity in any rotating machinery application." His perspective highlights that a well-designed housing not only enhances stability but also contributes to better heat dissipation and vibration control, ultimately leading to reduced maintenance costs and prolonged equipment life.

As industries increasingly seek to improve operational efficiency, identifying the top 10 motor bearing housing solutions becomes imperative. Innovations in materials, design, and manufacturing processes are paving the way for enhanced performance metrics. This article aims to explore these cutting-edge solutions, providing valuable insights for engineers and decision-makers looking to enhance their motor systems.

Understanding Motor Bearing Housing: Key Components and Functions

Motor bearing housings play a crucial role in the overall performance and longevity of motors. These components are specifically designed to securely hold the bearings in place, which support the rotor and minimize friction during operation. A typical motor bearing housing consists of several key elements, including the housing itself, seals, and lubrication systems. The design of the housing ensures proper alignment and stability of the bearings, while the seals protect against contaminants and retain the lubricant, significantly reducing wear and tear over time.

Understanding the functions of each component is essential for effective maintenance and optimal performance. The housing provides structural integrity, facilitating heat dissipation, which is vital for preventing overheating and prolonging service life. Meanwhile, the lubrication system plays an essential role in minimizing friction, allowing for smoother operation and decreased energy consumption. Additionally, the seals are critical in maintaining the integrity of the lubrication, ensuring that it remains effective by preventing leakage and contamination. Together, these elements form a cohesive unit that supports the motor's functionality and enhances its longevity.

Factors Affecting Performance in Motor Bearing Housing Solutions

When selecting motor bearing housing solutions, several key factors significantly impact their performance and longevity. First and foremost, the material of the housing plays a critical role. Materials such as cast iron or aluminum are preferred due to their strength, resistance to wear, and ability to withstand various environmental conditions. The right material not only enhances durability but also contributes to the overall efficiency of the motor system by reducing vibrations and heat generation.

Another vital factor is the precision of manufacturing. High-quality machining ensures that the components fit together perfectly, which minimizes the risk of misalignment and excessive friction. Additionally, the bearing design must accommodate lubrication effectively. Proper lubrication minimizes wear and tear on both the bearing and the housing, thereby extending the operational life of the motor. Lastly, environmental considerations, such as dust and moisture ingress, should be taken into account. Implementing sealing solutions can protect the bearings from contaminants, further enhancing performance and reliability in various operating conditions.

Top Materials Used in Motor Bearing Housing for Enhanced Durability

When it comes to enhancing the durability of motor bearing housings, the choice of materials plays a crucial role. The top materials commonly used include cast iron, aluminum, and various plastics. Cast iron is favored for its strength and excellent wear resistance. Additionally, it can withstand high temperatures, making it ideal for heavy-duty applications. On the other hand, aluminum offers a lighter weight solution with good thermal conductivity, making it suitable for applications where weight is a critical factor. Plastics, particularly engineered thermoplastics, are gaining popularity due to their corrosion resistance and lower weight, providing an excellent alternative for certain environments.

Tips for selecting the right material involve considering the specific application requirements, including load conditions, operating temperatures, and environmental factors. For example, corrosion-resistant materials should be prioritized in environments exposed to moisture or chemicals, while high-strength materials are more suitable for heavy loads. Moreover, it's essential to assess the ease of machining and assembly for the chosen materials to ensure optimal performance and longevity of the motor bearing housing.

Finally, combining materials can also be a viable option, leveraging the strengths of each. Hybrid designs, such as metal housings with plastic liners, can improve performance characteristics while minimizing weight and cost. As you evaluate bearing housing solutions, focus on selecting materials that consistently meet or exceed the operational demands of your application.

Innovative Designs in Motor Bearing Housing: Trends and Technologies

The performance and longevity of motor bearing housings are significantly influenced by innovative design trends and technologies. Recent advancements have focused on materials that offer increased strength and resistance to wear, which can enhance the overall durability of motor systems. For instance, new composite materials are being developed to minimize friction and heat generation, providing a more efficient operation. Additionally, the incorporation of smart technology into housing designs allows for real-time monitoring of bearing conditions, which can preemptively address potential failures and extend their lifetime.

Tips for choosing the right motor bearing housing include considering the operating environment and load conditions. It’s essential to select a housing design that not only fits the technical specifications of the motor but also enhances efficiency. Proper sealing technologies should also be prioritized to keep contaminants out, ensuring a clean operational environment. Furthermore, assess the compatibility of the housing with available lubrication systems to maintain optimal performance.

Emerging trends also highlight the importance of modular designs in motor bearing housings, promoting ease of maintenance and upgrades. This flexibility allows for quicker adaptations to changing operational needs without compromising reliability. Exploring these innovative designs can lead to significant improvements in performance outcomes for various applications, paving the way for more sustainable and efficient industrial practices.

Top 10 Motor Bearing Housing Solutions for Optimal Performance and Longevity

This chart displays the performance ratings of various innovative design factors in motor bearing housing solutions. Each factor is vital for ensuring optimal performance and longevity.

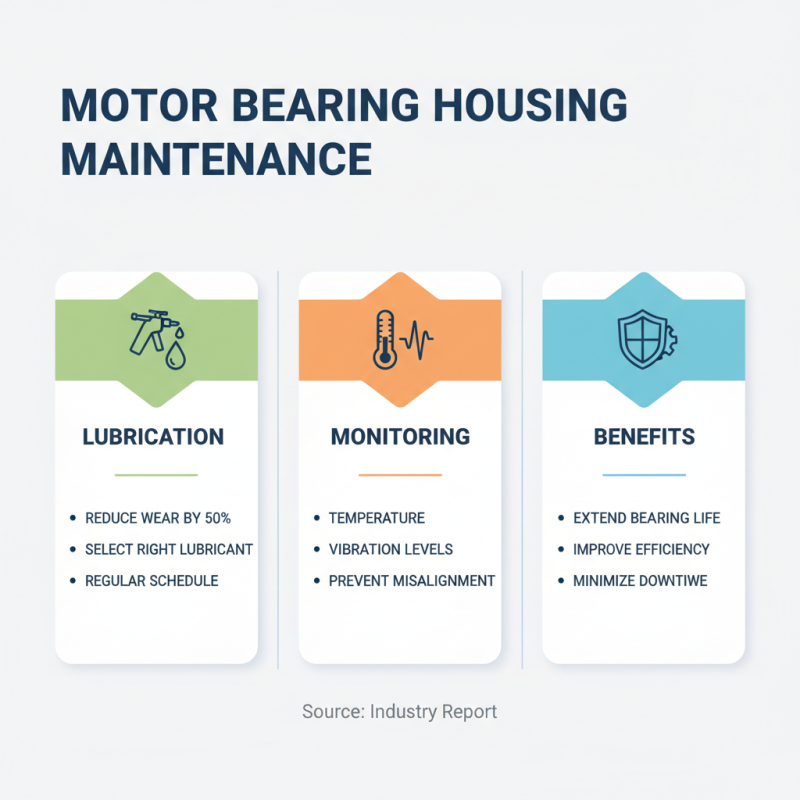

Maintenance Practices for Prolonging the Life of Motor Bearing Housings

Maintaining motor bearing housings is crucial for ensuring optimal performance and longevity. Regular maintenance practices not only extend the lifespan of the bearings but also improve overall efficiency, minimizing downtime and costly repairs. According to a recent industry report, proper lubrication can reduce wear by up to 50%, highlighting the importance of selecting the right lubricant and adhering to a regular maintenance schedule. Monitoring operating temperatures and vibration levels is also essential; excessive heat can indicate poor lubrication or misalignment, both of which can lead to premature failure.

**Tips for Maintenance:**

- Regularly inspect the seals and housing for signs of wear or damage, as seal failures are a common cause of lubricant leaks.

- Implement vibration analysis to detect early signs of imbalance or misalignment, which can prevent costly breakdowns.

Additionally, temperature control is vital for motor bearing housings. Data shows that every 10°C increase in operating temperature can reduce the bearing life by approximately 50%. Therefore, ensuring adequate cooling systems and ambient conditions can significantly enhance the durability of bearings. Cleaning the housing regularly to remove dirt and contaminants is also a worthwhile practice, as it helps maintain a stable environment for the bearings to operate efficiently.

**Tips for Temperature Control:**

- Use thermal imaging tools to monitor temperature variations in real-time, enabling proactive intervention when necessary.

- Consider installing cooling fins or fans if high temperatures are consistently detected to enhance air circulation around the motor assembly.

Related Posts

-

Understanding the Benefits of Choosing an Electric Motor House for Sustainable Living

-

2025 Guide: How to Choose the Best PSC Steering Box for Your Duramax

-

Unlocking Safety: The Essential Guide to Worldwide Door Latch Innovations

-

Exploring the Essential Functions and Innovations in Ford Steering Column Parts

-

The Ultimate Guide to Choosing the Right Commercial Door Latches for Maximum Security

-

2025 Top Drag Racing Steering Column Upgrades for Ultimate Performance