2025 Top 5 Aluminum Motor Housing Innovations You Need to Know

The automotive industry is on the brink of a significant transformation, driven by advancements in materials technology and manufacturing processes. In particular, aluminum motor housing has emerged as a game-changer, offering superior strength-to-weight ratios and enhanced thermal management capabilities. As per a recent report by Grand View Research, the global automotive aluminum market is expected to reach $180 billion by 2026, with a compound annual growth rate (CAGR) of 7.4%. This surge is largely attributable to the increasing demand for lightweight materials that improve vehicle efficiency and performance.

Innovations in aluminum motor housing designs are paving the way for more efficient electric and hybrid vehicles. With the continued rise of electric vehicle (EV) production, manufacturers are increasingly prioritizing components that not only reduce weight but also increase energy efficiency. According to a report by the International Energy Agency, global EV sales reached 6.65 million units in 2021, and this trend is projected to accelerate significantly. As the industry shifts towards sustainability and enhanced functionality, the next few years will see a wealth of innovations focusing on aluminum motor housing, setting the stage for the top innovations in 2025 that every stakeholder should keep an eye on.

Revolutionary Aluminum Alloys Enhancing Motor Housing Durability

The advancement of aluminum alloys is transforming the landscape of motor housing durability, particularly in the automotive and aerospace industries. According to a recent report from the Aluminum Association, the use of high-strength aluminum alloys in motor housing can enhance structural integrity, resulting in a performance increase of up to 15% compared to traditional materials. These innovative alloys are not only lighter but also offer superior resistance to corrosion and thermal fatigue, which are critical for maintaining engine performance under extreme conditions.

Among the top innovations leading this charge are 7075 and 6061 aluminum alloys. The 7075 alloy, known for its high strength-to-weight ratio, is increasingly being utilized in electric vehicle (EV) motor housings, providing manufacturers with the capability to meet stringent weight and efficiency demands. Furthermore, a study by ResearchGate highlights that components made from these advanced alloys can significantly extend the lifespan of motors, reducing maintenance costs by approximately 20% over five years. As the demand for more efficient, durable motor housings intensifies, these revolutionary aluminum alloys are set to become the standard, reshaping the future of motor design and application.

2025 Top 5 Aluminum Motor Housing Innovations You Need to Know

This chart illustrates the percentage of durability improvement for the top five innovations in aluminum motor housings expected in 2025. Each innovation represents a unique advancement in aluminum alloys designed to enhance the durability of motor housing components.

Smart Manufacturing Techniques Transforming Aluminum Housing Production

The evolution of smart manufacturing techniques is playing a pivotal role in revolutionizing the production of aluminum motor housings. As industry leaders strive for greater efficiency and sustainability, the integration of advanced robotics and automation systems has enabled manufacturers to optimize their operations significantly. Through the use of Internet of Things (IoT) devices, real-time data analytics allows for proactive monitoring of production lines, reducing downtime and enhancing overall productivity. This data-driven approach not only minimizes waste but also improves the precision and quality of aluminum housing components.

Another notable innovation in aluminum housing production is the incorporation of additive manufacturing, or 3D printing, which is transforming design capabilities and production speeds. This technique enables engineers to create complex geometries that were previously difficult or impossible to achieve with traditional methods. Additionally, the ability to rapidly prototype parts and iterate designs fosters a more agile manufacturing process, allowing companies to respond quickly to market demands. Together, these smart manufacturing innovations are setting new industry standards for aluminum motor housings, driving forward a more efficient and environmentally-friendly production landscape.

Eco-Friendly Innovations in Aluminum Housing Recycling Processes

The growing emphasis on eco-friendly innovations in aluminum housing recycling processes highlights a significant trend towards sustainable manufacturing. Companies are increasingly adopting advanced recycling techniques that minimize waste and reduce energy consumption. For instance, recent innovations showcase how aluminum scrap can be effectively repurposed, thereby cutting down on emissions and promoting a circular economy. These developments not only ensure the responsible use of resources but also align with global efforts to address environmental concerns.

Moreover, the integration of sustainable practices within various sectors, such as the automotive and electronics industries, signals a collective move towards greener solutions. By focusing on recycling aluminum and enhancing the efficiency of manufacturing processes, companies are setting benchmarks for environmental responsibility. This shift is essential, especially considering the rising demand for sustainable products and solutions that cater to environmentally conscious consumers. With continuous advancements, the landscape of aluminum housing innovations is poised for remarkable transformation, promising a cleaner future.

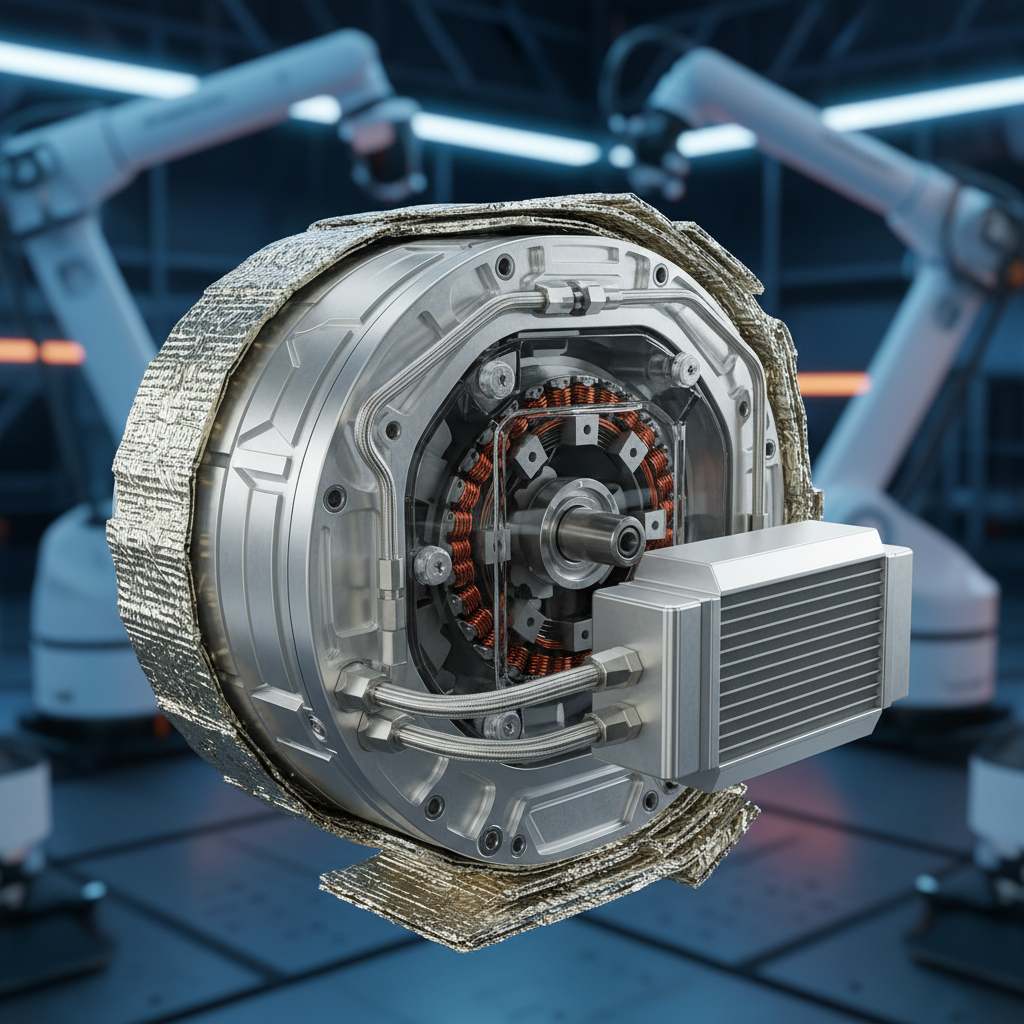

Advanced Thermal Management Solutions in Aluminum Motor Applications

As the automotive industry progresses toward more efficient electric vehicles, advanced thermal management solutions in aluminum motor applications have become increasingly crucial. The global automotive heat shield market is projected to grow significantly, with estimates indicating a rise from USD 5.2 billion in 2021 to over USD 8 billion by 2028, reflecting an annual growth rate of around 7.5%. This surge is driven by the growing demand for lightweight materials, such as aluminum, which offer excellent thermal conductivity while minimizing vehicle weight.

Recent innovations in aluminum surface engineering are enabling breakthroughs in thermal management. Engineers have developed techniques that enhance aluminum surfaces, improving their ability to manage heat dissipation effectively. This topographical contrast allows for the patterning of emitted infrared radiation, which can lead to significant advancements in cooling systems as well as self-cleaning and anti-icing technologies. Such advancements are essential for modern electric motors, where overheating can lead to performance issues and reduced lifespan. With these innovations, aluminum is positioned to play a vital role in optimizing thermal management strategies, ultimately enhancing the reliability and efficiency of electric vehicle powertrains.

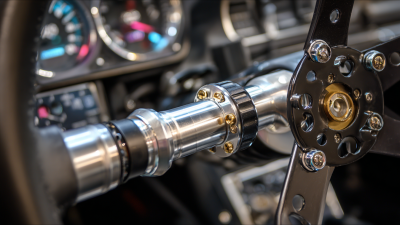

Integration of IoT Technology for Enhanced Performance Monitoring in Motors

In the evolving landscape of motor manufacturing, the integration of IoT technology stands out as a transformative force. This innovative approach not only enhances performance monitoring but also revolutionizes the way aluminum motor housings are designed and utilized. By embedding sensors within the motor housing, manufacturers can collect real-time data on temperature, vibrations, and operational efficiency. This data enables predictive maintenance, reducing downtime and prolonging the lifespan of motors, which is crucial in industries reliant on constant operations.

Tips for implementing IoT in motor technology include beginning with a clear understanding of your monitoring needs. Assess what specific metrics are most critical for your operations, and choose sensors that efficiently track these parameters. Additionally, ensure that your data collection system is capable of processing information in real-time to make timely decisions based on the data received.

Another vital consideration is the seamless integration of IoT systems with existing motor technologies. Look for solutions that offer compatibility with current systems, minimizing disruption during implementation. Engaging with IoT specialists can facilitate this transition, ensuring that you leverage the full potential of the technology while maximizing the benefits of your aluminum motor housings.

2025 Top 5 Aluminum Motor Housing Innovations You Need to Know - Integration of IoT Technology for Enhanced Performance Monitoring in Motors

| Innovation | Key Features | Benefits | IoT Integration |

|---|---|---|---|

| Smart Thermal Management | Real-time temperature monitoring sensors | Improved efficiency and longevity | Remote temperature data access |

| Predictive Maintenance Algorithms | Machine learning-based risk assessments | Reduced downtime and repair costs | Automated alerts for maintenance schedules |

| Dynamic Load Balancing | Real-time load distribution sensors | Maximized performance and reduced wear | Data analytics for optimal load management |

| Integrated Vibration Monitoring | Sensitive accelerometers for vibration analysis | Immediate detection of mechanical issues | Continuous vibration data tracking |

| Wireless Communication Protocols | Enhanced data transmission capabilities | Increased connectivity and versatility | Real-time data sharing across devices |

Related Posts

-

The Ultimate Guide to Choosing the Right Commercial Door Latches for Maximum Security

-

Top 10 Essential Tips for Choosing Kenworth Tilt Steering Column Parts

-

Exploring the Advantages of PSC Steering Columns: Performance, Safety, and Innovation

-

Maximize Your Ride: The Ultimate Guide to Non-OEM Car Parts for Every Budget

-

Exploring the Essential Functions and Innovations in Ford Steering Column Parts

-

Top 10 Tips for Upgrading Your Drag Racing Steering Column for Maximum Performance