Top Questions About Tilt Steering Column Parts for Peterbilt Trucks in 2025

The evolution of truck design has consistently aimed to enhance driver comfort and vehicle control, an area where tilt steering columns play a pivotal role. As outlined in recent industry analyses, tilt steering columns, particularly in the context of Peterbilt trucks, are crucial for ensuring ergonomic optimization and operational efficiency. Market data suggests that the global commercial vehicle steering system market is projected to reach $20 billion by 2027, reflecting the importance of innovative steering components such as the Peterbilt tilt steering column parts.

In 2025, as fleet operators seek to improve their vehicles' handling and driver satisfaction, understanding the working mechanisms and maintenance of these parts becomes essential. Industry reports highlight that approximately 30% of truck-related accidents can be attributed to inadequate steering system performance. Thus, an in-depth knowledge of Peterbilt tilt steering column parts is not just beneficial; it's vital for ensuring safety and reliability in long-haul operations. Addressing common questions and concerns regarding these components will empower fleet managers and drivers alike to make informed decisions, ultimately enhancing the overall functionality of Peterbilt trucks.

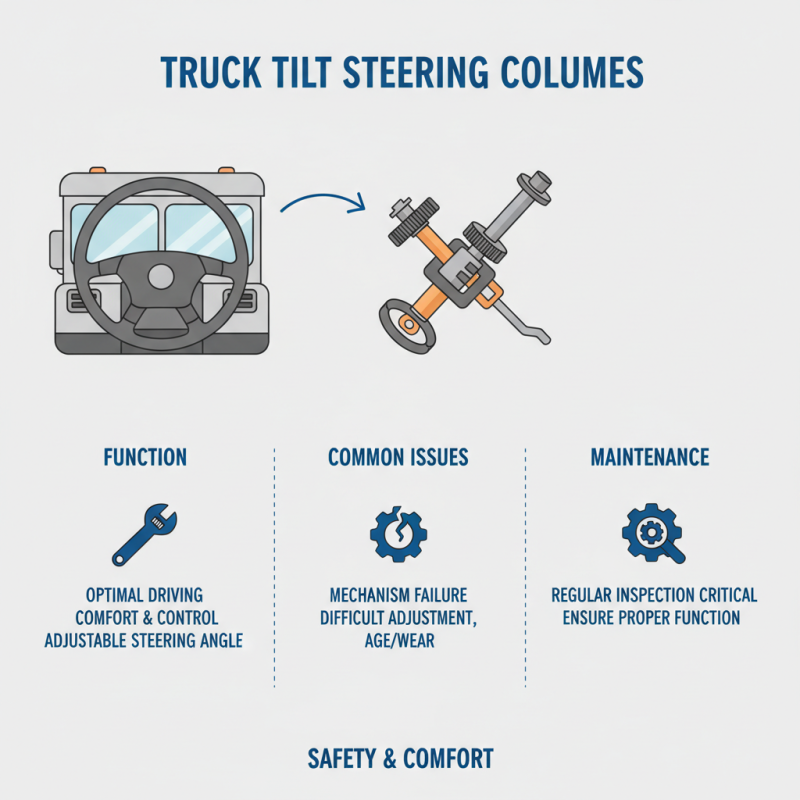

Overview of Tilt Steering Column Features in Peterbilt Trucks

Tilt steering columns in trucks are essential components that enhance driver comfort and control. These systems allow the steering wheel to be adjusted vertically, accommodating various driver heights and preferences. This flexibility helps reduce fatigue during long hauls and improves overall handling of the vehicle. In 2025, the features of tilt steering columns in trucks have evolved to incorporate advanced materials and precision engineering, which not only improve durability but also enhance safety with better ergonomics.

Another significant aspect of tilt steering columns is their integration with modern technological advancements. Many newer models include optional electronic adjustments, whereby the steering position can be altered at the push of a button. This innovation caters to drivers' diverse needs and preferences, making it easier for them to find the perfect driving position quickly. Additionally, improved locking mechanisms ensure that the steering column remains securely in place while driving, providing an added layer of safety and control. All these features contribute to a more pleasant and efficient driving experience in heavy-duty trucks.

Key Components of Tilt Steering Columns for 2025 Peterbilt Models

The tilt steering column is a critical component for enhancing driver comfort and control in heavy-duty trucks, particularly in the 2025 model year. These columns allow drivers to adjust their steering wheel position, enabling a tailored fit that can improve visibility and reduce fatigue during long hauls. Key components of tilt steering columns include the tilt mechanisms, locking systems, and the column housing. According to industry analysis, over 60% of drivers report that adjustable steering columns significantly contribute to overall ergonomics and driving comfort, making them an essential element in truck design.

When considering upgrades or replacements for tilt steering columns in Peterbilt trucks, it’s important to focus on the quality of materials used in the components. For instance, heavy-duty steel and reinforced plastics are widely recommended for durability and longevity. Additionally, industry reports suggest that incorporating advanced locking mechanisms can enhance safety, reducing the risk of unexpected steering changes while driving. Regular inspections of the tilt mechanism and locking systems can also prevent mechanical failures, ensuring that drivers maintain optimal control.

Tips: Regularly check the tilt steering mechanism for any signs of wear and tear, as early detection can prevent more significant issues down the line. Investing in high-quality aftermarket components can also improve the performance and functionality of your steering column system. Lastly, consider consulting with a professional mechanic when making adjustments to ensure proper installation and operation.

Common Issues with Tilt Steering Column Parts in Peterbilt Trucks

Tilt steering columns are essential components in many modern trucks, providing drivers with the flexibility to adjust their steering angles for optimal comfort and control. However, common issues may arise with these parts, particularly as the vehicles age or due to wear from frequent adjustments. One frequent problem is the failure of the tilt mechanism, which can lead to difficulty in changing the steering wheel position. This can affect driving comfort and safety, making regular inspections critical to ensure it functions properly.

Another common issue that truck owners may encounter is the loosening of the steering column hardware over time. Vibrations and constant use can lead to bolts and connections becoming loose, resulting in wobbling or uneven steering. Additionally, the internal components, such as the tilt lever or cable, may suffer from wear and tear, causing them to malfunction. Addressing these issues early can prevent more significant problems down the line, ensuring the steering column remains reliable and safe to use. Regular maintenance and awareness of these common issues will go a long way in preserving the functionality of tilt steering columns in trucks.

Maintenance Tips for Tilt Steering Column Systems in Peterbilt Vehicles

Maintaining a tilt steering column system is crucial for ensuring a smooth and safe driving experience in heavy-duty vehicles. Regular inspections and maintenance can prevent issues that compromise steering integrity and driver comfort. One of the essential maintenance tips is to periodically check the tilt mechanism for any signs of wear or damage. Look for loose bolts, unusual noises, or resistance when adjusting the steering wheel. Addressing these issues early can save time and money on more extensive repairs later.

Another important aspect of maintenance is lubrication. The tilt steering column consists of various moving parts that require appropriate lubrication to operate efficiently. Make it a routine to apply the recommended lubricant to the pivot points and bearings. This will reduce friction, prevent corrosion, and extend the lifespan of the component.

Lastly, ensure that the electrical connections related to the tilt mechanism are secure and free from corrosion. Faulty wiring can lead to unexpected failures, compromising the steering system. Regularly inspecting these connections will help maintain the overall functionality of the tilt steering column, promoting both safety and performance on the road. By adhering to these maintenance tips, drivers can enhance the longevity and reliability of their steer systems, ensuring a better driving experience.

Top Questions About Tilt Steering Column Parts for Peterbilt Trucks in 2025 - Maintenance Tips for Tilt Steering Column Systems in Peterbilt Vehicles

| Question | Answer | Maintenance Tips |

|---|---|---|

| What are common issues with tilt steering columns? | Common issues include looseness, failure to lock, and uneven adjustment. | Regularly inspect for wear and ensure all fasteners are tight. |

| How often should I lubricate the tilt mechanism? | Lubrication should be done every 6 months or as needed. | Use a suitable grease and ensure the area is clean before application. |

| Can I adjust the height of the steering column? | Yes, most tilt steering columns have a height adjustment feature. | Adjust only when stationary to avoid accidents. |

| What tools do I need for tilt steering column maintenance? | Basic hand tools such as wrenches, screwdrivers, and lubrication tools. | Ensure you have a clean workspace and proper lighting. |

| What are the signs that my steering column needs replacement? | Signs include persistent play, excessive rust, or mechanical failure. | If you notice any of these signs, consult a professional. |

Future Innovations in Tilt Steering Column Technology for Trucks

As we look toward the future of trucking technology, the evolution of tilt steering column parts is poised to redefine driver experience and safety. The integration of advanced materials and smart technologies is expected to enhance both the functionality and ergonomics of tilt steering systems. For instance, lightweight composites may become standard, allowing for easier adjustments and reducing overall vehicle weight. Furthermore, incorporating sensors into the steering column can provide real-time feedback to drivers, adjusting the steering position to promote optimal comfort and reduce fatigue on long hauls.

Another promising innovation is the potential for greater connectivity within the cabin. Tilt steering columns could feature integrated controls for various vehicle functions, all accessible from the steering wheel. This would streamline operations and enable drivers to maintain focus on the road while managing critical systems efficiently. Furthermore, the continued development of adaptive steering technologies may also allow for personalization settings, accommodating individual driver preferences and enhancing overall driving performance. As these innovations unfold, the tilt steering column will not only improve the functionality of trucks but also contribute to safer and more enjoyable driving experiences.

Related Posts

-

2025 Top Drag Racing Steering Column Upgrades for Ultimate Performance

-

2025 How to Choose the Right Motor Housings for Your Project Needs

-

2025 Guide: How to Choose the Best PSC Steering Box for Your Duramax

-

The Ultimate Guide to Choosing the Right Commercial Door Latches for Maximum Security

-

2025 Top 5 Aluminum Motor Housing Innovations You Need to Know

-

Why Upgrading to PSC Steering Box Duramax Enhances Your Vehicle's Performance