How to Choose the Right Electric Motor for Your Home Projects and Needs

Choosing the right electric motor house for your home projects is essential for achieving efficiency and effectiveness in various applications. Electric motors are an integral part of numerous household systems, from powering appliances to driving tools and even facilitating automation in gardening and home improvement tasks. With a plethora of options available, understanding how to select the most suitable electric motor is crucial for homeowners looking to optimize their DIY endeavors.

When considering the right electric motor for your home, it's important to assess your specific needs, including the power requirements and the type of work you intend to perform. Factors such as torque, speed, and energy efficiency should all be taken into account to ensure that the chosen motor can handle the demands of your projects. Additionally, understanding the differences between types of electric motors—such as AC and DC motors—can help streamline your decision-making process.

Ultimately, the right electric motor house not only enhances the performance of your projects but also contributes to the safety and longevity of your equipment. By informing yourself about the various options and their applications, you can make a confident choice that aligns with your home improvement goals and supports sustainable practices.

Understanding the Basics of Electric Motors and Their Types

Electric motors are essential components in a wide range of home projects,

offering versatility and

efficiency in various applications.

Understanding the basics of electric motors and their types is crucial when

selecting the right one for your specific needs. Generally, electric motors

can be categorized into two main types:

AC

(Alternating Current) and

DC

(Direct Current) motors.

AC motors are commonly used in household appliances, such as refrigerators and

washing machines, due to their ability to generate a continuous rotational motion.

According to the International Electrotechnical Commission (IEC), AC motors account

for nearly 70% of the total motors sold globally,

reflecting their prevalence in everyday use.

DC motors, on the other hand, are favored for applications requiring precise speed

control and torque, such as in robotics or electric vehicles. These motors are capable

of providing high starting torque, making them suitable for tasks like powering tools

or smaller machinery.

A report from the U.S. Department of Energy highlights that advancements in motor

technology, especially in the efficiency of DC motors, can lead to energy savings of

up to 20% in residential applications. This

underscores the importance of understanding the operational advantages of each type

to make an informed decision for your home projects.

Identifying Your Project Requirements and Motor Specifications

When embarking on home projects that require electric motors, it is crucial to begin by identifying your specific project requirements. Consider the nature of the task at hand—will you be driving a stationary appliance like a fan, or powering a dynamic tool such as a saw? Different applications have distinct demands for torque, speed, and power consumption. According to a recent industry report from the Electric Motor Association, nearly 70% of electric motors used in residential projects fall within the range of 0.5 to 5 horsepower, making it essential to match the motor's capabilities with your task's requirements.

Additionally, understanding motor specifications is vital for selecting the right fit. Common specifications include voltage rating, RPM (revolutions per minute), and efficiency ratings. Motors designed for higher efficiency can save homeowners significant energy costs over time, with reports indicating that energy-efficient motors can reduce electricity consumption by up to 30%. When analyzing these specifications, it's important to account for the duty cycle of your project; is it a continuous operation or an intermittent one? Selecting a motor with an appropriate duty rating will ensure optimal performance and longevity.

Tips: Always calculate the total load that the motor will need to handle, factoring in any potential additional weight or resistance. Moreover, consider the environment where the motor will be used—will it be exposed to dust, moisture, or extreme temperatures? This understanding will guide you to select motors with suitable enclosure types and temperature ratings, thus ensuring safety and efficiency in your home projects.

Evaluating Motor Power Ratings and Efficiency for Home Use

When selecting an electric motor for home use, evaluating the power ratings and efficiency is crucial to meet the demands of your specific projects. An electric motor's power rating, typically measured in horsepower (HP) or watts (W), indicates its capability to perform work. For instance, a standard motor used in household applications usually ranges from 1/4 to 3 HP, providing ample power for tasks such as powering tools or appliances. According to the U.S. Department of Energy, motors can account for as much as 70% of industrial electricity consumption, highlighting the importance of choosing an efficient model that minimizes energy waste in home settings as well.

Efficiency ratings of electric motors are often expressed as a percentage, representing the ratio of mechanical output to electrical input. Higher efficiency motors, exceeding 90%, not only help reduce electricity bills but also lower the environmental impact of energy consumption. The International Energy Agency (IEA) notes that upgrading to more efficient motors can lead to significant savings in energy costs, estimated at around $25 billion annually in the U.S. alone. Additionally, understanding the service factor and starting torque ratings can further enhance the motor's performance in residential applications, ensuring it can handle the workload without overheating or damaging the connected equipment. By carefully considering these parameters, homeowners can select the appropriate motor that not only fulfills their project requirements but also promotes energy efficiency and cost-effectiveness.

How to Choose the Right Electric Motor for Your Home Projects and Needs

| Motor Type | Power Rating (HP) | Efficiency (%) | Ideal Applications | Voltage (V) |

|---|---|---|---|---|

| AC Induction Motor | 1.5 | 85 | Pumps, Fans | 230 |

| DC Brushless Motor | 1 | 90 | Power Tools, Small Appliances | 12 |

| Brush DC Motor | 0.5 | 80 | Toys, Robotics | 6 |

| Stepper Motor | 0.4 | 75 | 3D Printers, CNC Machines | 24 |

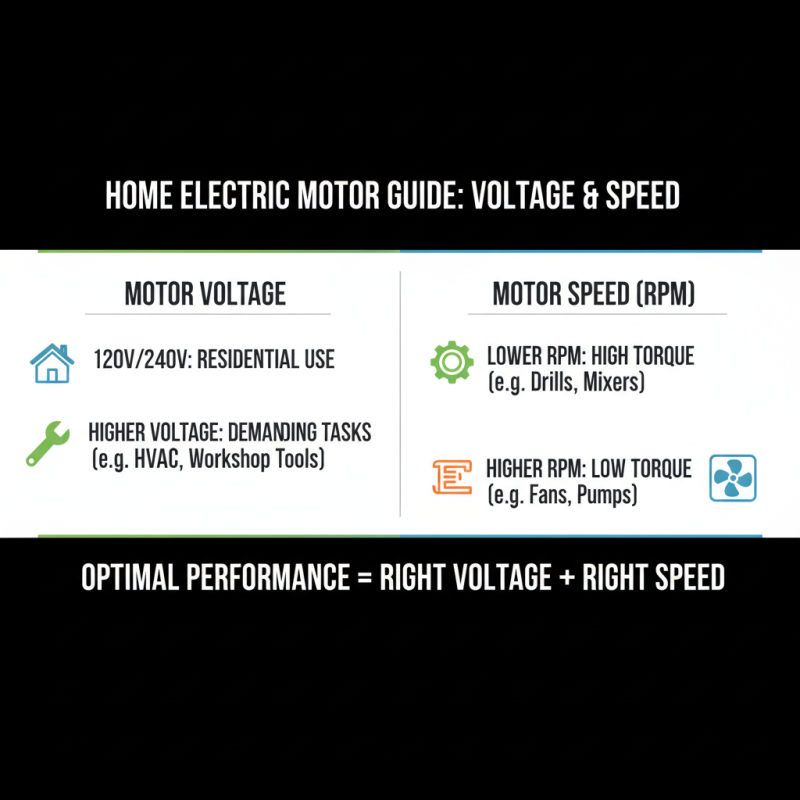

Selecting the Right Motor Voltage and Speed for Your Needs

When selecting the right electric motor for your home projects, understanding motor voltage and speed is crucial to ensure optimal performance. The voltage of the motor determines its power supply requirements and can impact the stable operation of your equipment. Generally, residential applications tend to favor lower voltages, such as 120V or 240V, depending on the specific needs of your project. For more demanding tasks, a higher voltage motor might be required to achieve efficient operation without overheating or drawing excessive current.

When considering motor speed, it is essential to match the speed of the motor with the requirements of your application. Different projects necessitate different speeds; for example, a fan might require a high-speed motor, while a conveyor belt may benefit from a slower, more controlled operation. Additionally, variable speed motors can offer versatility, allowing users to adjust performance based on their specific tasks.

**Tips:**

- Always check the voltage compatibility with your existing electrical system to avoid potential hazards.

- Calculate the required speed based on the load and application to prevent inefficient performance.

- Consider future projects when selecting motor specifications to make sure your choice remains versatile for various tasks.

Installing and Maintaining Electric Motors for Optimal Performance

Proper installation and maintenance of electric motors are crucial for ensuring their optimal performance in home projects. When installing an electric motor, it’s essential to start by selecting a suitable location that allows for adequate ventilation and minimizes exposure to moisture or dust. The motor should be mounted firmly to reduce vibrations, which can lead to premature wear and malfunctions. Additionally, ensure that all electrical connections are secure and compliant with safety standards to prevent any operational hazards.

Regular maintenance is vital to prolong the lifespan and efficiency of electric motors. Routine checks should include inspecting belts and pulleys for wear, ensuring bearings are lubricated, and monitoring motor temperatures during operation. Cleaning the motor and its surrounding area helps prevent debris buildup, which can impede performance. Finally, keeping an eye on electrical connections for signs of corrosion or loose wiring is essential for maintaining safe and effective operation. Implementing these practices fosters not only the reliability of the motor but also enhances safety in home projects.

Related Posts

-

Understanding the Benefits of Choosing an Electric Motor House for Sustainable Living

-

Top Questions About Tilt Steering Column Parts for Peterbilt Trucks in 2025

-

Top 10 Tips for Upgrading Your Drag Racing Steering Column for Maximum Performance

-

2025 Top Drag Racing Steering Column Upgrades for Ultimate Performance

-

2025 Guide: How to Choose the Best PSC Steering Box for Your Duramax

-

2025 How to Choose the Right Motor Housings for Your Project Needs